Development

Batteries have to be qualified for specific applications,

requiring the measurement of all relevant battery parameters:

- Voltage

- Spectral impedance

- Capacity

- Temperature

An integrated fully automatic calculation of the model parameters facilitates the analysis.

Round cells of the popular formats 18650, 21700 and 26650 can be inserted directly and loaded with currents of up to 5A.

Recommended device: CTA (Round Cell Adapter)

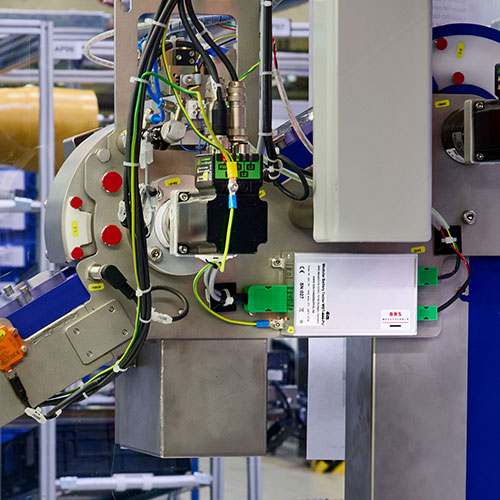

Cell Inspection

(Begin-of-line-test)

For incoming inspection of large quantities of cells, measurement speed combined with in-depth testing is important.

Our compact instruments can easily integrated into production lines for batteries. Within just 0.4 seconds they measure:

- Voltage

- AC impedance

- DC impedance

For high quantities, the 5-channel MBT-X5 is recommended; for shorter cycle times, the measuring frequencies can be adjusted.

Recommended devices: MBT family

EoL Testing

Battery modules are assembled from individual cells and electrically connected in series or parallel. The quality of the welded connections and the correct arrangement of the cells is verified by an AC internal resistance measurement.

In the final test, it should also be verified whether the module is suitable for operation; this is usually done by a DC internal resistance measurement.

By replacing the DC pulse measurement with an AC frequency measurement, an overall test can be performed with only one device.

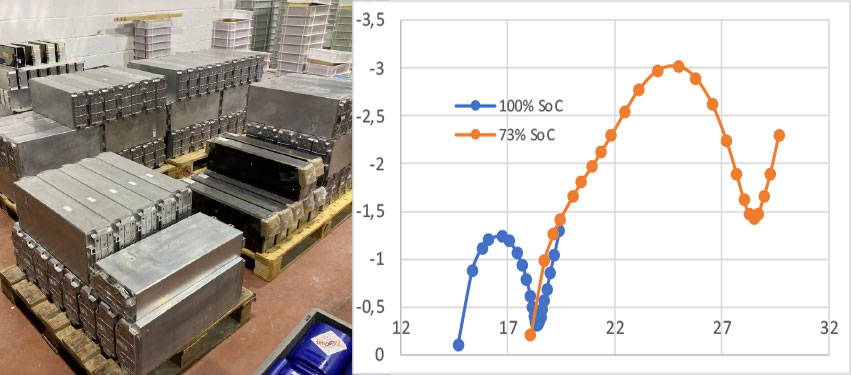

Second Life

For a second use, the remaining capacity (SoH) must be determined. The comparison of impedance spectra provides statements about the battery condition in a few minutes. An integrated model parameter function facilitates the analysis.

Recommended devices: BIM2B